Efficient heat management is vital for the reliability and performance of modern electronic and automation systems. As components become smaller and more powerful, they generate increasing amounts of heat that must be efficiently dissipated to maintain stability and extend service life. An industrial-grade aluminium heat sink plate offers an effective, lightweight, and cost-efficient solution for these thermal challenges, especially in high-power electronics and automated equipment.

Understanding the Role of Aluminium Heat Sink Plates

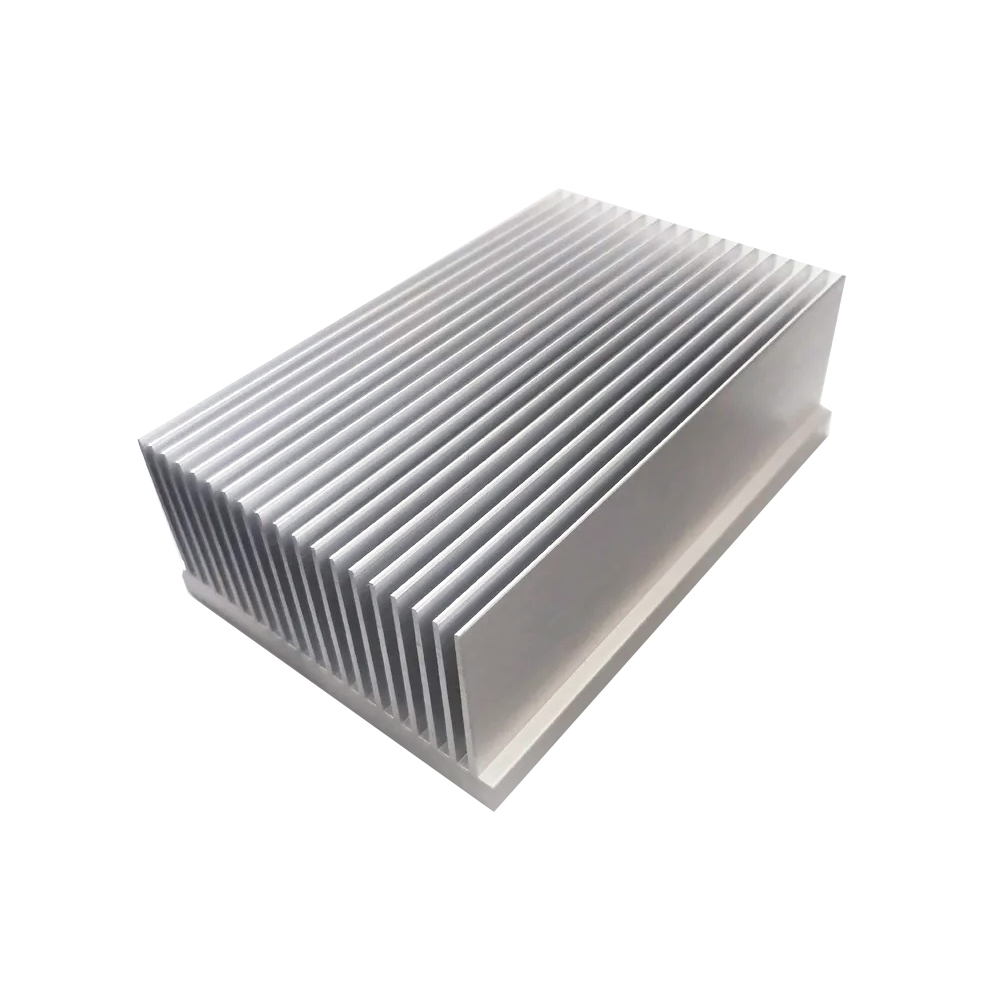

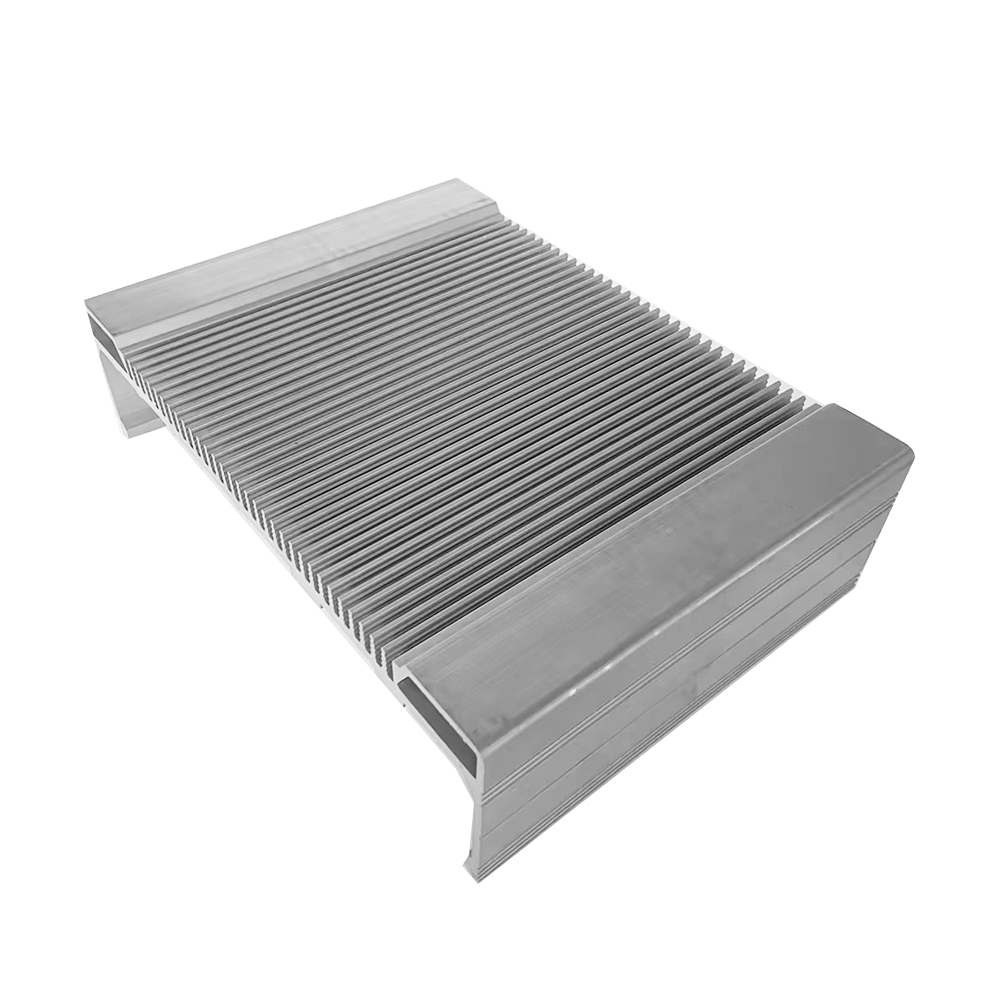

An aluminium heat sink plate is a flat, precision-engineered thermal conductor designed to draw heat away from components such as power modules, inverters, IGBTs, and control boards. It uses aluminium’s natural advantages — excellent thermal conductivity, corrosion resistance, and mechanical strength — to transfer heat quickly from the heat source to the surrounding air or cooling medium.

Compared with copper, aluminium provides a better balance between performance, cost, and weight. For industrial equipment and automation systems where consistent operation and durability are priorities, aluminium heat sink plates ensure steady thermal control without adding unnecessary load to the system’s structure.

Applications in Power Electronics and Automation

In power electronics, efficient thermal management directly affects device reliability and lifespan. Aluminium heat sink plates are commonly used in:

- Inverters and converters for solar, wind, and industrial systems

- Power supplies for communication and automation equipment

- Servo drives and motor control units

- LED drivers and lighting systems

- Battery management and energy storage modules

Automation equipment, in particular, relies heavily on stable temperature control to maintain precision and performance. By integrating custom aluminium heat sink plates, manufacturers can achieve uniform heat distribution across high-power components, reducing the risk of overheating and operational failure.

aluminium heat sink plate supplier

Key Advantages of Aluminium Heat Sink Plates

High Thermal Efficiency: Aluminium provides excellent heat transfer capability, making it suitable for high-density and high-frequency applications.

Lightweight Strength: Aluminium’s favorable strength-to-weight ratio allows easy integration into compact designs without compromising durability.

Corrosion Resistance: The natural oxide layer on aluminium protects it from oxidation, extending its service life even in demanding industrial environments.

Cost-Effectiveness: Compared to copper or composite materials, aluminium offers strong performance at a lower cost, which benefits mass production.

Flexible Fabrication: Through extrusion, CNC machining, or bonded-fin techniques, aluminium heat sink plates can be manufactured to match precise specifications.

Custom Design Support: Aluminium’s excellent machinability enables OEM customization—from surface treatment to structural optimization—to suit different applications.

OEM Design and Customization Options

For companies developing advanced power and automation systems, off-the-shelf solutions often fall short. That’s where custom aluminium heat sink plate design comes in.

Manufacturers can tailor plate thickness, fin geometry, and surface finishes based on the required thermal performance and mechanical constraints.

Typical customization options include:

- CNC precision machining for complex mounting interfaces

- Anodizing or powder coating for enhanced corrosion resistance

- Embedded heat pipes or liquid channels for active cooling systems

- Integration with aluminium enclosures or extruded profiles for compact designs

At the engineering stage, thermal simulations and performance testing ensure the plate meets each system’s specific power density and heat load requirements.

Why Aluminium Heat Sink Plates Are Preferred in Industry

Industrial buyers value aluminium heat sink plates for their balance of performance, adaptability, and long-term reliability. In automation systems, downtime caused by overheating can disrupt production lines and damage sensitive equipment. By incorporating properly designed aluminium heat sink plates, system integrators can maintain consistent temperatures and extend component life cycles.

In renewable energy, power electronics, and data communication sectors, where heat dissipation is critical, these plates play a key role in ensuring efficient operation under heavy load conditions.

Aluminium Heat Sink Plate Manufacturer

Hao Mei: Reliable Partner for Aluminium Thermal Solutions

Hao Mei is a professional aluminium profile manufacturer and supplier in China, with years of expertise in producing aluminium heat sink plates and custom aluminium cooling components for industrial clients worldwide. The company provides full-service solutions — from material selection and precision extrusion to CNC machining and surface treatment.

By combining advanced production technology with strict quality control, Hao Mei supports OEM and system integrator partners in achieving stable thermal performance and long product lifespan across diverse applications.

To explore Hao Mei’s custom aluminium heat sink plate solutions, visit https://www.alu-haomei.com/ and connect with our technical team for tailored support on your next project.