As the demand for sustainable architecture grows, so too does the need for building materials that balance performance with environmental responsibility. One standout solution is aluminum window extrusion profiles – a cornerstone of modern energy-efficient building designs. These profiles not only offer strength and design flexibility but also play a vital role in thermal insulation, long-term durability, and aesthetic integration.

Why Aluminum Window Extrusion Profiles Are a Game-Changer

Aluminum has long been favoured in architectural and construction projects due to its lightweight, corrosion-resistant nature. But when extruded into precise window frame profiles, it becomes a tool for enhanced performance and energy efficiency. The extrusion process allows manufacturers to create complex cross-sections with minimal waste, offering excellent structural integrity with slim, elegant lines.

Aluminum window extrusion profiles have evolved significantly in recent years. With thermal break technology, powder coatings, anodised finishes, and high-precision fabrication, they’re not just frames – they’re active contributors to a building’s energy strategy.

Boosting Energy Efficiency in Modern Construction

A major benefit of using aluminum window frames is the improved thermal performance that comes from innovative extrusion techniques. Through thermal break technology – where a resin or polyamide barrier is inserted between the inner and outer profile – heat transfer is significantly reduced. This creates a thermal barrier that prevents indoor heat from escaping during winter or entering during summer.

Combined with double or triple-glazed glass systems, thermally broken aluminum window profiles can dramatically cut a building’s heating and cooling demands. For commercial buildings striving for green building certifications such as BREEAM or LEED, this is a significant advantage.

Aluminium Extrusion Profiles For Windows

Versatility in Architectural Design

Aluminum window profiles offer unmatched flexibility when it comes to architectural creativity. The extrusion process allows manufacturers to produce a wide variety of profile shapes – from standard casement and sliding windows to bespoke curtain walling systems and slimline profiles for minimalistic designs.

What makes aluminum window extrusion profiles particularly appealing to architects and project planners is the ability to customise. Whether the project requires hidden vents, integrated shading systems, or flush-mounted frames for a sleek facade, aluminum profiles can be tailored precisely.

Moreover, the range of finishes available – including powder coating in any RAL colour and anodising in various shades – ensures the profiles can blend seamlessly with diverse architectural styles, from heritage renovations to ultramodern commercial complexes.

Durability That Lowers Lifetime Costs

Durability is a crucial consideration in commercial and industrial buildings, especially where maintenance costs need to be kept low. Aluminum extrusion profiles boast outstanding corrosion resistance, particularly when treated with anodising or marine-grade powder coating. This means aluminum frames are ideal even for coastal or humid environments where other materials might fail prematurely.

The long service life of aluminum – often exceeding 30 years with minimal upkeep – translates into real cost savings over time. For large-scale property developers or contractors managing public sector infrastructure, the use of durable aluminum profiles can help ensure long-term returns on investment.

Sustainability and Recyclability

One of aluminum’s strongest selling points is its sustainability. Not only is it fully recyclable, but recycled aluminum retains the same quality and strength as primary aluminum. This makes it a responsible material choice for developers keen on reducing their carbon footprint.

In the extrusion process, waste is minimal, and leftover scrap is routinely recycled. Additionally, many suppliers now source low-carbon aluminum, contributing further to the reduction of embodied energy in construction projects. For architects and planners working on sustainable design certifications or government-backed green building initiatives, aluminum extrusion profiles check every box.

Aluminum window Frame System

Meeting Regulatory Standards and Performance Expectations

Today’s aluminum window extrusion profiles are manufactured to comply with a wide range of international and regional standards, including EN 755, EN 12020, and EN 15088 for structural integrity and finish quality. When paired with high-performance glazing, they meet or exceed energy codes in many regions – including the UK’s Part L regulations for energy performance in buildings.

Fire resistance, acoustic insulation, and wind-load resistance can also be engineered into the design, making these profiles suitable for high-rise buildings, schools, hospitals, and airports.

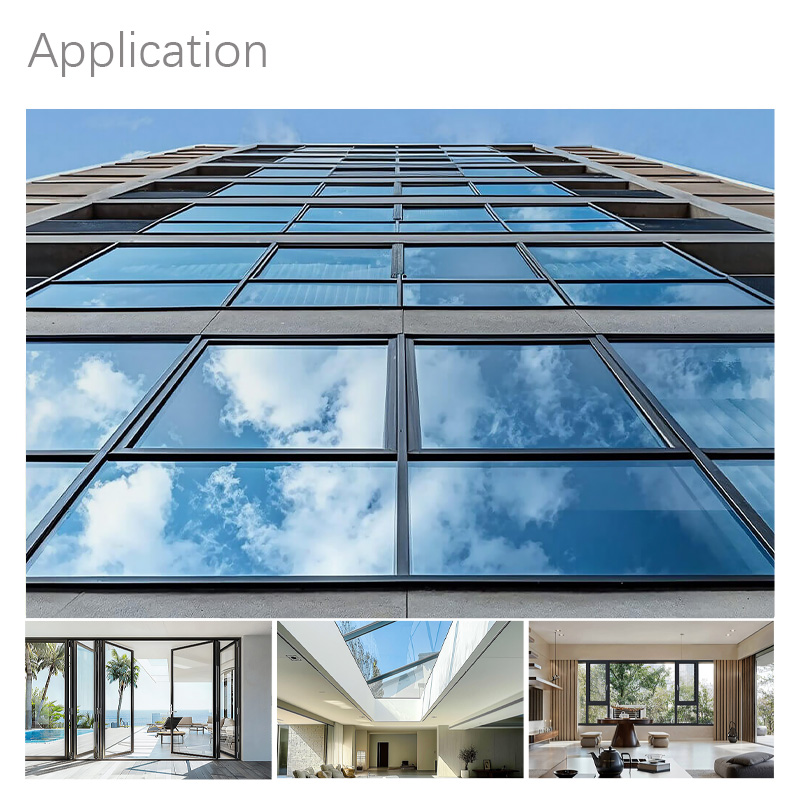

Application Examples in Commercial Projects

Aluminum window extrusion profiles are widely used in various sectors, including:

- Office buildings – where large glass areas require strong yet slim framing systems.

- Retail centres – where aesthetic appeal and energy savings can boost property value.

- Hospitality – hotels and resorts benefit from the corrosion resistance and custom finish options.

- Healthcare facilities – where hygiene, ventilation, and long-term durability are key.

- Educational institutions – providing light-filled, energy-efficient environments for learning.

These applications highlight the adaptability of aluminum profiles across diverse building types and environments.

Choosing the Right Aluminum Extrusion Supplier

For project managers and procurement officers, selecting a reliable aluminum extrusion supplier is crucial. Look for a manufacturer that offers:

- Custom extrusion capabilities

- In-house tooling and die design

- Full quality control traceability

- Surface treatment options (anodising, powder coating, etc.)

- Technical support and design consultation

Partnering with an experienced supplier ensures not just timely delivery and consistent quality, but also the flexibility to meet evolving project needs.

Aluminium Extrusion profiles for windows

Recommended Solution from Haomei Aluminum

At Haomei Aluminum, we specialise in the design and manufacture of aluminum window extrusion profiles tailored for energy-efficient building applications. Our profiles are made using high-quality 6000-series alloys, designed with thermal breaks, and available in a wide variety of finishes and configurations. Whether you require standard window systems or custom architectural extrusions, our production capabilities are built to support commercial-scale demands with precision and consistency.

We offer end-to-end support from die design and extrusion to surface finishing and logistics. With an eye on international compliance and environmental responsibility, Haomei Aluminum is your strategic partner for high-performance aluminum extrusion solutions.

Final Thoughts

Aluminum window extrusion profiles are more than just a structural component – they’re a vital part of achieving sustainability, design freedom, and performance excellence in modern construction. As developers and architects continue to push for greener, smarter buildings, aluminum extrusions will remain a core building block in achieving those ambitions.

By investing in the right profiles and suppliers, commercial projects can reduce operating costs, enhance building value, and contribute to a more sustainable built environment.