Industrial aluminum profiles are not merely structural elements—they are the silent enablers of modern industrial evolution. In 2025, these extruded components continue to dominate the fabrication landscape with their unparalleled adaptability, corrosion resistance, and formability. Their lightweight nature and high tensile strength make them indispensable in industries racing toward automation, sustainability, and miniaturization.

Across sectors as diverse as aerospace and renewable energy, industrial aluminum profiles serve as the backbone of innovation. Their ability to be cut, connected, and repurposed with minimal tooling fosters a new era of design agility. Let’s explore five standout industrial applications that are redefining how industrial aluminum profiles are being used in 2025.

1. Smart Factory Automation Systems

As Industry 4.0 matures, industrial aluminum profiles are integral to the assembly lines of the future. Their use in modular machine frames, linear motion systems, and protective enclosures is foundational to the growing automation ecosystem.

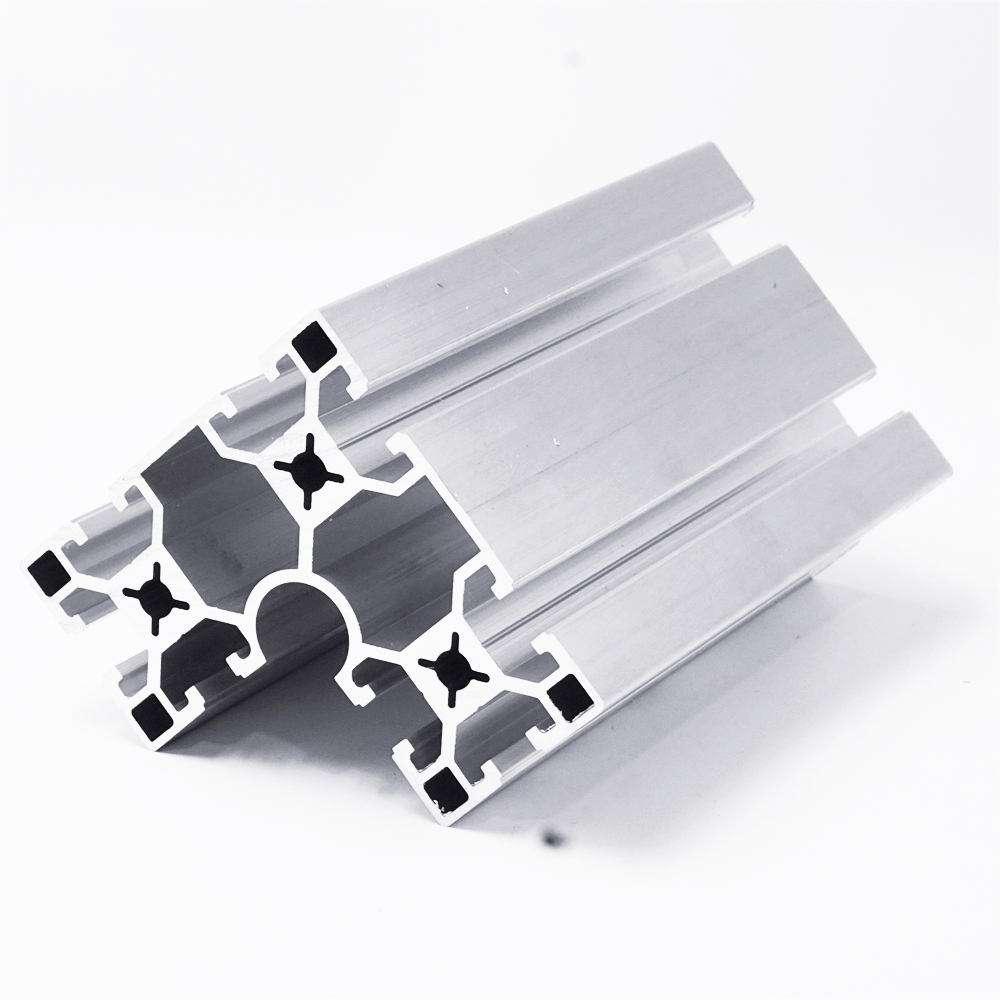

These profiles provide a skeletal framework that can be rapidly assembled or reconfigured—ideal for the fluid demands of smart manufacturing. Whether supporting robotic arms or conveyor systems, their T-slot configurations allow for effortless attachment of sensors, guides, and brackets without the need for welding.

Their anodized surfaces resist wear in high-friction environments, ensuring longevity in continuous operation. As factories become increasingly self-optimizing, industrial aluminum profiles enable an infrastructure that evolves alongside the machines it supports.

2. Renewable Energy Infrastructure

In 2025, the shift toward renewable energy isn't optional—it’s essential. Industrial aluminum profiles have become central to this green revolution. Their most visible use is in the structural framing of photovoltaic (PV) systems, including both rooftop arrays and sprawling solar farms.

Engineered for extreme weather tolerance, these profiles support panels without succumbing to rust or UV degradation. Their low weight means easier transportation and faster assembly—key benefits when constructing megawatt-scale installations in remote or rugged terrain.

Wind energy also leans on industrial aluminum profiles, especially for housing turbine control systems and lattice tower internals. The metal’s recyclability aligns perfectly with the sustainability ethos of renewable technologies.

Industrial T-slot Aluminum Profile Manufacturer

3. Electric Vehicle (EV) Manufacturing

EV production in 2025 is all about efficiency, and industrial aluminum profiles are helping to power that drive. Inside EV factories, these profiles form lightweight yet rigid structural components for both production machinery and the vehicles themselves.

Battery tray housings, cooling enclosures, and even crash absorption elements in EVs are now commonly extruded from high-grade aluminum alloys. This substitution from heavier steel reduces vehicle weight, improving range and overall performance without compromising on safety.

Furthermore, the profiles’ design flexibility accommodates complex geometries and tight tolerances, ideal for EV manufacturers racing to prototype and launch new models.

4. Aerospace and Aeronautics

The aerospace sector has long trusted aluminum, but 2025 sees even greater utilization of precision industrial aluminum profiles in next-gen aerial technology. From UAV (unmanned aerial vehicle) chassis to aircraft interior structures, these profiles are prized for their high stiffness-to-weight ratio.

Drones and lightweight aircraft benefit from profiles that provide aerodynamic rigidity while minimizing mass—crucial for fuel economy and flight stability. On the ground, industrial aluminum profile-based service trolleys and maintenance stands dominate airport logistics, offering portability and rust-proof resilience.

Their machinability ensures that tolerances required for aeronautical components can be achieved without the exorbitant cost, keeping production lean and agile.

industrial aluminum profile supplier

5. Cleanroom and Medical Equipment

In an era where hygiene protocols are more rigorous than ever, industrial aluminum profiles have carved out a critical role in the cleanroom and healthcare equipment space. They form the backbone of modular partitions, mobile instrument carts, and sterile workstations.

The material’s non-porous surface and compatibility with disinfectants make it ideal for environments requiring microbiological control. Aluminum frames can be seamlessly integrated with antistatic panels or medical-grade plastics to meet strict ISO classifications.

Furthermore, their ease of assembly—often using standardized connectors—means cleanroom layouts can be rapidly adapted as processes evolve or regulations tighten.

Conclusion

In 2025, industrial aluminum profiles are more than materials—they’re strategic tools for modern industry. Their role spans sectors on the cutting edge of technology and sustainability. With a unique blend of durability, lightweight performance, and design flexibility, industrial aluminum profiles underpin everything from solar farms to surgical labs.

As material science advances and demand for modularity surges, industrial aluminum profiles will continue to evolve—adapting to smarter, cleaner, and more connected industrial futures.