Powder coating extruded T-slot aluminium profiles play a crucial role in modern industrial and manufacturing environments. These versatile aluminium structures are not only essential for building robust frameworks and equipment but also provide a durable and aesthetic surface finish that enhances performance and longevity. As industrial aluminium extrusion technology advances, powder coating has become one of the most popular and effective finishing methods for improving both appearance and protection.

Understanding Industrial Aluminium Extrusion

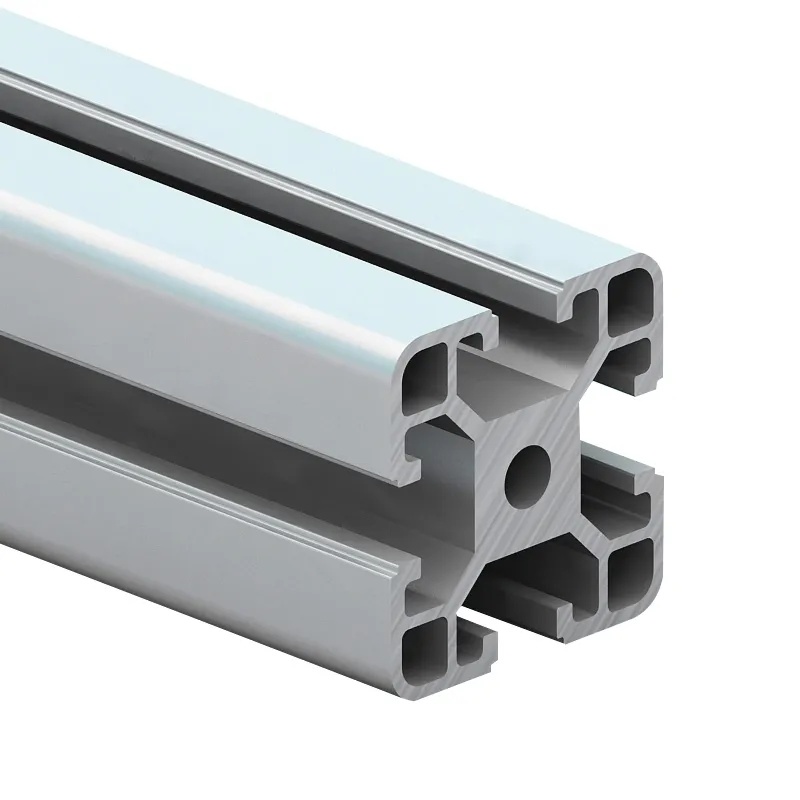

Industrial aluminium extrusion is a precision manufacturing process in which heated aluminium billets are forced through a die to create continuous profiles with a consistent cross-section. These profiles, often referred to as T-slot aluminium profiles or industrial aluminium extrusions, serve as modular building components in automation systems, factory equipment, conveyors, enclosures, and custom machinery.

The 6000 series aluminium alloy, particularly 6061 and 6063, is widely used in industrial aluminium extrusion due to its excellent strength, machinability, and corrosion resistance. The resulting extrusions can be further processed through anodizing or powder coating to enhance surface properties and visual appeal.

Industrial Aluminium Extrusion Factory In China

Why Powder Coating is Ideal for Extruded Aluminium Profiles

Powder coating is a dry finishing process where electrostatically charged powder particles are applied to the aluminium surface and cured under heat to form a uniform, hard layer. For extruded T-slot aluminium profiles, this method offers several advantages:

- Superior Corrosion Resistance: Powder coating provides a dense, protective barrier that prevents oxidation and extends the service life of aluminium profiles, even in harsh industrial or outdoor environments.

- Enhanced Aesthetic Appeal: The coating delivers a smooth, even finish available in a variety of colors and textures, such as silver, black, bronze, or custom tones. This makes it ideal for architectural and machinery applications.

- Durability and Scratch Resistance: The cured powder layer resists chipping, fading, and abrasion, maintaining a clean, professional appearance even under demanding use.

- Eco-Friendly Process: Powder coating produces minimal waste and does not emit volatile organic compounds (VOCs), aligning with sustainable manufacturing standards.

Applications of Powder-Coated T-Slot Aluminium Profiles

Powder-coated industrial aluminium extrusions are widely used across multiple sectors due to their adaptability and strength. Common applications include:

- Machine frames and automation systems

- Industrial workstations and production lines

- Safety enclosures and guarding systems

- Building frameworks and modular constructions

- Transportation and logistics equipment

Their modular T-slot design allows users to assemble and modify structures easily without welding, using standard connectors and accessories. This flexibility significantly reduces installation time and labor costs while ensuring high structural integrity.

T slot aluminium aluminum profile applications

Surface Treatment Options for Industrial Aluminium Extrusions

While powder coating is one of the most popular surface finishing choices, other options such as anodizing and electrophoresis are also available. Each serves different purposes depending on the end-use requirements:

- Anodizing enhances corrosion resistance and provides a metallic finish.

- Powder coating offers color versatility, UV protection, and thicker coverage.

- Electrophoresis coating delivers a fine, uniform layer ideal for decorative applications.

By combining extrusion technology with advanced finishing options, aluminium profiles can be tailored for specific environmental and functional demands.

Haomei Industrial Aluminium Extrusion Solutions

Haomei specializes in producing high-performance industrial T-slot aluminium extrusions engineered for both construction and manufacturing sectors. Each profile is crafted from premium 6000 series aluminium alloy, ensuring outstanding strength, precision, and resistance to corrosion.

Haomei’s extrusions are available in diverse shapes—round, square, rectangular, and hexagonal—and can be customized to meet project-specific requirements. To accommodate varying industrial applications, Haomei offers multiple surface finishes, including anodizing, powder coating extruded T-slot aluminium profiles, and electrophoresis, in a range of colors such as silver, black, bronze, and wood grain.

With flexible length options, fast delivery, and reliable global shipping (via container or bulk vessel), Haomei provides an efficient supply chain solution for businesses worldwide. Free samples are available to help customers evaluate quality and compatibility before bulk ordering.

Whether used for modular machine frames, factory automation, or architectural frameworks, Haomei’s T-slot aluminium profiles deliver consistent performance and durability. Each extrusion is designed for easy assembly and long-term use, meeting the evolving needs of modern industry.

industrial aluminium extrusion supplier

Conclusion

Powder coating extruded T-slot aluminium profiles have become an essential component in industrial aluminium extrusion solutions. Their combination of mechanical strength, corrosion resistance, and aesthetic flexibility makes them ideal for a broad range of commercial and industrial applications.

Haomei continues to advance in this field, offering precision-engineered aluminium extrusion systems backed by reliable manufacturing expertise and customizable options. For businesses seeking durable, high-quality aluminium profiles with superior finishing, Haomei provides dependable solutions tailored to your project’s demands.