Window frames have evolved from rudimentary wooden constructions to highly engineered components that balance form, function, and longevity. Among the contenders in modern architecture, aluminum has risen to prominence—not merely as a structural choice but as a hallmark of contemporary design. Its versatility, strength-to-weight ratio, and sleek profile have positioned aluminum window frame profiles as a gold standard across residential, commercial, and industrial applications.

What Are Aluminum Window Frame Profiles?

Aluminum window frame profiles are precision-formed extrusions made from high-grade aluminum alloys. They serve as the foundational skeleton that supports glazing, hardware, and sealing systems in windows. Through the extrusion process, heated aluminum billets are forced through dies to create intricate, consistent cross-sectional shapes tailored to various window styles.

The result is a high-performance frame that maintains dimensional stability across extreme climates, supports heavy glazing loads, and allows for tight tolerances. These profiles are more than just structural elements—they are a synthesis of engineering precision and aesthetic intent.

Types of Aluminum Window Frame Profiles

Sliding Window Profiles

Designed for horizontal or vertical movement, sliding profiles feature interlocking components and concealed rollers. These are ideal for maximizing space utilization, particularly in urban apartments and commercial storefronts.

Casement Window Profiles

Casement profiles are hinged on the side and open outward or inward like a door. They often incorporate multiple chambers to enhance insulation and accommodate various locking systems.

Fixed and Tilt-Turn Window Profiles

Fixed window profiles provide uninterrupted views and superior air-tightness, while tilt-turn profiles offer dual functionality—tilting for ventilation and turning for full access. Both require robust frame geometries to ensure rigidity and aesthetic cleanliness.

Thermal Break vs. Non-Thermal Break Profiles

Thermal break profiles incorporate a polyamide or resin barrier between the interior and exterior aluminum sections, significantly reducing heat transfer. In contrast, non-thermal break profiles are suitable for interiors or mild climates where insulation demands are minimal.

Aluminum Window Frame Profile Manufacturer

Key Benefits of Aluminum Window Frame Profiles

Structural Integrity and Lightweight Design

Aluminum combines tensile strength with featherlight mass, allowing for slender yet robust frames. This facilitates larger glazing areas without compromising safety or stability—an architect’s dream for open, light-filled spaces.

Corrosion Resistance and Weatherproofing

Unlike ferrous metals, aluminum naturally develops a thin oxide layer that protects it from rust and corrosion. With additional coatings, it withstands salty coastal air, acid rain, and intense UV exposure—making it suitable for diverse environments.

Design Flexibility and Architectural Compatibility

Extruded profiles can be customized into virtually any shape, allowing for innovation in window geometry and joinery. Whether the design language is ultramodern or classically ornate, aluminum adapts seamlessly.

Sustainability and Recyclability

Aluminum is one of the most recyclable construction materials. Recycling consumes only 5% of the energy required for primary production. This endows aluminum frames with a low environmental footprint and strong green credentials.

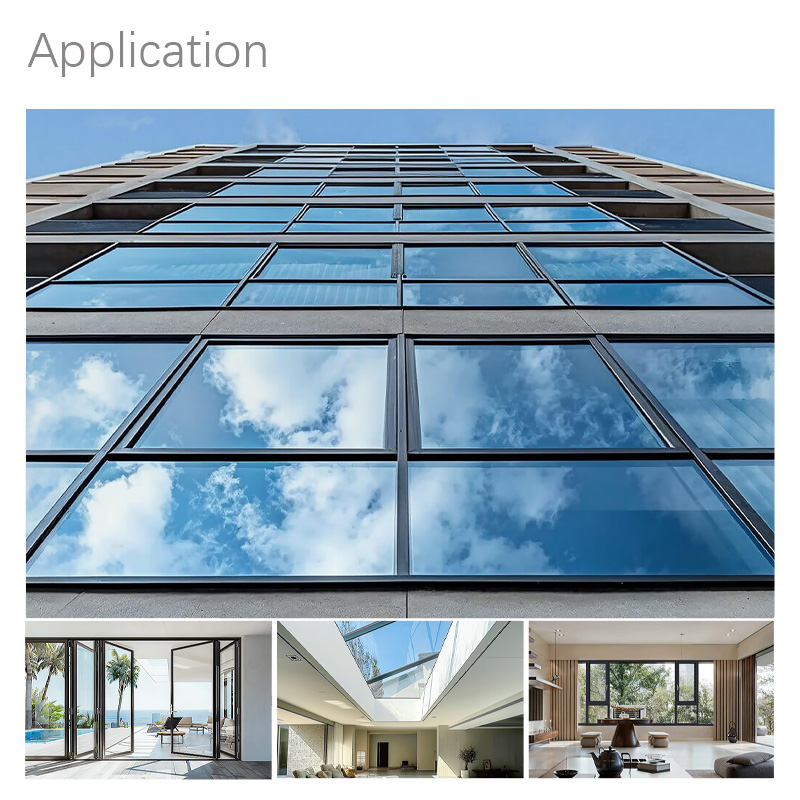

Common Applications in Residential and Commercial Architecture

Modern Home Designs and Minimalist Aesthetics

In upscale residential settings, aluminum frames pair well with floor-to-ceiling windows and frameless transitions. Their crisp lines complement the pared-back ethos of minimalism.

High-Rise Buildings and Curtain Wall Systems

Commercial skyscrapers leverage the strength of aluminum to support vast curtain wall façades. The material’s load-bearing capabilities and compatibility with fire-rated glazing make it indispensable in high-density urban architecture.

Industrial and Institutional Settings

Warehouses, hospitals, and educational facilities favor aluminum for its durability, ease of maintenance, and long life cycle. Profiles can be tailored for security glazing and impact resistance, making them fit for mission-critical applications.

Aluminum Window Frame Extrusion Supplier

Comparing Aluminum Profiles with Other Framing Materials

Aluminum vs. uPVC

While uPVC offers excellent insulation at a lower upfront cost, it lacks the rigidity and longevity of aluminum. Over time, uPVC is prone to warping and discoloration, especially under intense sun exposure.

Aluminum vs. Wood

Wood exudes natural warmth but requires continual maintenance. Aluminum, in contrast, offers a maintenance-free solution with similar aesthetic appeal when finished with woodgrain coatings.

Cost-Performance Analysis

Aluminum profiles may come at a premium, but their lifecycle cost is significantly lower. They outlast most alternatives and require fewer repairs, making them a strategic investment over decades.

Customization Options and Surface Treatments

Powder Coating and Anodizing

Powder coating offers a tough, UV-resistant finish in virtually any color. Anodizing enhances corrosion resistance while preserving the metal’s natural sheen. Both treatments elevate the durability and visual appeal of the profile.

Color, Texture, and Finish Versatility

Aluminum frames can be made to mimic wood, stone, or matte textures. This allows them to blend into traditional facades or stand out in avant-garde settings.

Compatibility with Glazing Systems

Profiles are engineered to accept single, double, or triple-glazing systems. Integrated seals and thermal spacers further improve performance, ensuring comfort and energy savings.

Conclusion

Aluminum window frame profiles represent the convergence of durability, efficiency, and design sophistication. Their adaptability across climates and architectural styles, combined with unmatched longevity and recyclability, makes them a preferred choice for the future of fenestration. Whether you’re crafting a glass-wrapped penthouse or retrofitting a commercial block, aluminum profiles offer a resilient and elegant solution that endures.